Industrial-Grade

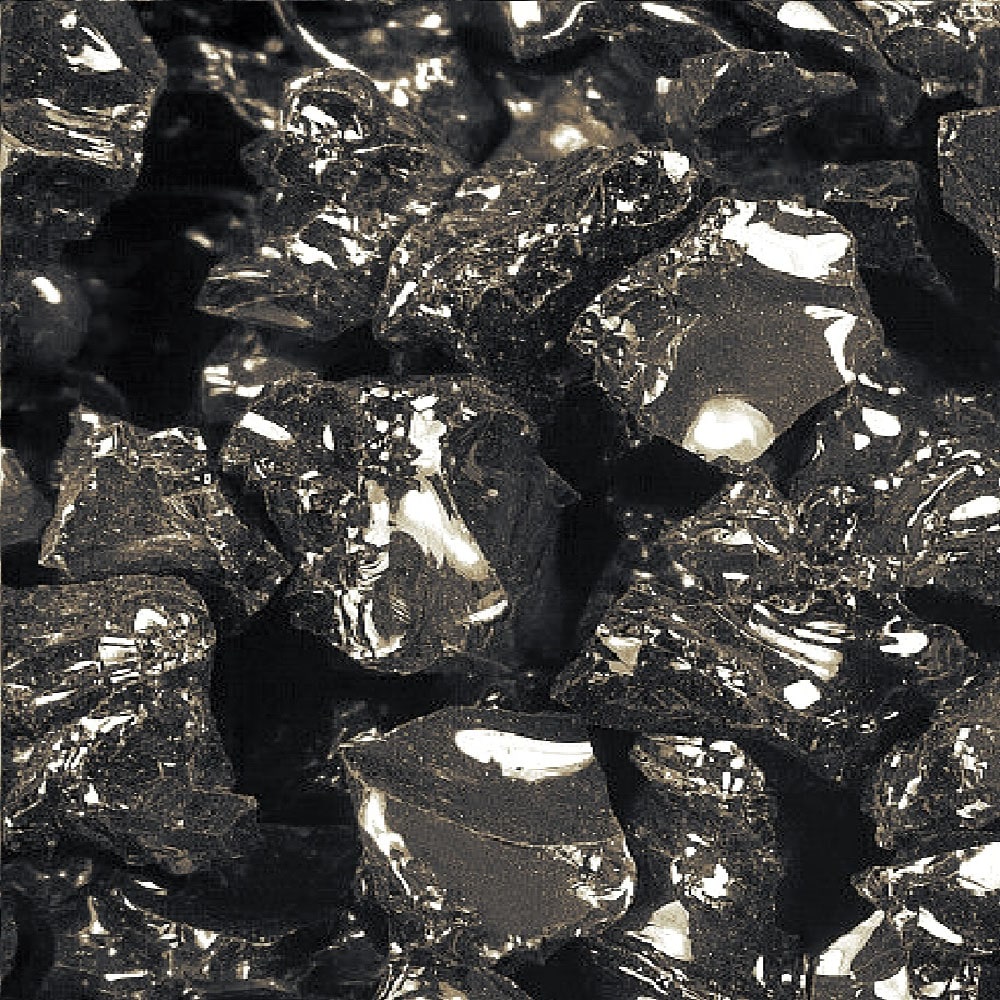

Nickel Slag

Abrasive

ISO 11126 compliant angular nickel-slag grit for professional shipyard, heavy steel, and industrial surface preparation.

"Precision-engineered abrasive delivering consistent Sa 2½ – Sa 3 surface standards"

Why Nickel-Slag Abrasive?

"As tough and angular as the Balkans themselves"

ISO-certified iron silicate with superior angular particle geometry, engineered for industrial surface preparation demanding consistent performance.

Angular Cutting Action

Irregular, sharp-edged particles create aggressive cutting profiles for efficient coating removal and optimal anchor pattern formation on steel substrates.

Superior Physical Properties

Mohs hardness ≥ 6, optimal density 2.8–3.9 kg/dm³, and ultra-low moisture content (≤ 0.2%) ensure consistent performance and extended equipment life.

Health & Safety Compliant

Free crystalline silica ≤ 1% (XRD verified), low conductivity ≤ 250 µS/cm, and minimal chloride content ≤ 0.0025% for safer operations.

Available Size Grades

Stock ISO ranges compliant with ISO 11126-5 Table 1 specifications

Standard Stock Sizes

| Size Range | Applications | Status |

|---|---|---|

0.2–0.5 mm | Fine surface prep | In Stock✓ |

0.2–1.0 mm | General blasting | In Stock✓ |

0.2–1.4 mm | Medium profile | In Stock✓ |

0.2–2.0 mm | Heavy duty cleaning | In Stock✓ |

0.2–2.8 mm | Maximum profile | In Stock✓ |

0.5–1.0 mm | Precision work | In Stock✓ |

0.5–1.4 mm | Standard operations | In Stock✓ |

1.0–2.0 mm | Heavy steel prep | In Stock✓ |

1.4–2.8 mm | Aggressive removal | In Stock✓ |

Custom Granulation Services

Our advanced processing facilities enable custom granulation and packaging tailored to your exact specifications. We offer flexible solutions designed to meet specific industrial requirements while maintaining ISO compliance and quality standards.

Custom Blends

Tailored particle size distribution

Volume Flexibility

From trial quantities to bulk supply

Quality Assurance

Full ISO compliance maintained

Partnership Focus

Long-term collaboration benefits

Custom Range Capabilities

Within ISO limits: max particle ≤ 3.15 mm • fines < 0.2 mm ≤ 5%

Size ranges aligned with leading EU suppliers: JBlast, Scangrit, Eurogrit standards

Industrial Applications

Proven performance across demanding industrial sectors requiring consistent Sa 2½ – Sa 3 surface standards

Marine & Shipyard

Ship hulls, ballast tanks, cargo holds, deck areas, and offshore structures

Heavy Steel Fabrication

Structural steel, bridges, industrial frameworks, and heavy machinery components

Storage Tanks & Vessels

Industrial storage tanks, pressure vessels, pipelines, and petrochemical equipment

Industrial Coatings

Surface preparation for protective coatings, paint removal, and maintenance operations

Consistent Sa 2½ – Sa 3 Surface Standards

Engineered particle geometry delivers optimal anchor patterns with grade-appropriate profile when used with proper blasting equipment

Technical Specifications

Comprehensive technical data ensuring compliance with international standards and specifications

ISO 11126-5 Certified Properties

| Property | Specification / Typical Value |

|---|---|

| Standard | ISO 11126-5 (Nickel/Ferronickel Slag); test methods ISO 11127-1/-2/-3/-4/-5/-6/-7 |

| Particle shape | Grit (G) — angular/irregular |

| Free crystalline silica | ≤ 1% (XRD) |

| Apparent density | 2.8–3.9 kg/dm³ |

| Hardness | Mohs ≥ 6 |

| Moisture | ≤ 0.2% |

| Conductivity (aqueous extract) | ≤ 250 µS/cm |

| Water-soluble chlorides | ≤ 0.0025% (mass) |

Global Packaging & Logistics

Comprehensive shipping solutions with flexible packaging options designed for efficient global distribution and optimal material protection

Bulk Cargo Options

- Bulk Vessels:

Direct loading for large volume shipments (1000+ tons)

- Container Loading:

20ft/40ft containers with optimized loading patterns

- Flexible Scheduling:

Regular sailing schedules and charter vessel options

European Distribution

- Jumbo Bags (FIBC):

1-1.8 ton capacity with discharge spouts

- Euro Pallets:

Standard EU pallets for easy warehouse handling

- Small Bags:

25/30/50 kg options for smaller operations

Shipping Terms

- FOB Terms:

Free On Board from origin ports

- CIF/CFR Available:

Cost, Insurance, Freight arrangements

- Documentation:

Complete export documentation and certificates

Quality Protection & Documentation

Moisture Protection

Sealed packaging prevents moisture absorption during transport

ISO Documentation

Complete ISO designation and test certificates included

Tracking & Support

Real-time shipment tracking and logistics support

Frequently Asked Questions

Global Contact Network

Connect with our industrial abrasive specialists worldwide for technical consultation, quotations, and logistics support

US & Global Office

Primary contact for global inquiries, technical specifications, and international project coordination

European Office

Specialized in European market requirements, FIBC packaging, and Euro pallet distribution

Ready to Specify Your Requirements?

Share your target surface profile (µm), coating system, and preferred size range — our specialists will recommend the optimal grade and logistics solution